Bristol

Commercial Vehicles was a major manufacturer of bus and coach chassis between 1908 and 1983, building 31,760 units in 75 years. They were based on Bath Road, Brislington, Bristol. Between 1955 and 1964 they also built 1,170 lorries

for British Road Services and in 1958 they built 2 railbus chassis for British Railways.

Early history

George White and partner started Bristol Tramways Company in 1875. They first used motorbuses in 1906 and two years later they built their first bus chassis.

The Motor Department was initially based at the tram depot in Brislington, on the Bath Road. During 1907 the bus fleet was transferred to a site at Filton. Then in 1910 the company decided to build aeroplanes. The best place for this work was the sheds at Filton, so motor repairs and construction returned to Brislington. The tram depot had become too small, so a new 4 acre site, known as the Motor Constructional Works, was established nearby, off Chatsworth Road. This became the site of the Bristol chassis factory.

In May 1914 Bristol supplied its first bus to another operator, a C50 charabanc to Imperial Tramways at Middlesbrough. After World War 1 volume chassis production got underway. The company soon established a good reputation as a builder of solid, reliable vehicles.

In 1929 the Great Western Railway bought a controlling interest in the tramway company, but the bus operations were transferred to Western National in 1931. This brought Bristol Tramways and its manufacturing activities into the Tilling Group.

Other Tilling companies started buying Bristol bus chassis. Most of these were taken to another Tilling concern Eastern Coach Works of Lowestoft, for bodying.

Bristol Commercial Vehicles (BCV) was created in 1943 as a subsidiary of Bristol Tramways (part of Tilling Group). The 1947 Transport Act saw the nationalisation of the Tilling Group into the British Transport Commission (BTC). So, BCV found itself restricted to selling chassis to state-owned BTC operators. In 1955 BCV became an separate company owned by BTC.

Underfloor engine chassis

Bristol's first underfloor engine bus/coach was the

LS

– (Light

Saloon) an integral model new in 1950. Then in 1957, in a bid to reduce weight and hence operating costs, they introduced what would become the very successful

MW

(Medium

Weight) chassis.

In 1960 Bristol built the

SU

(

Small

Underfloor engine) chassis for rural operations. For details of all bus and coach chassis Bristol produced between 1908 and 1960,

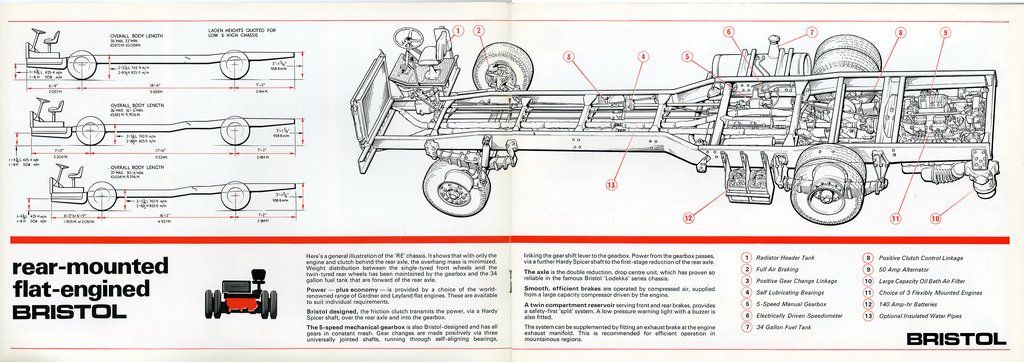

click here. Finally in 1962 come the

RE

(

Rear

Engine) model.

In 1965 Leyland Motors Ltd bought a 25% shareholding in Bristol (and Eastern Coach Works), so that their vehicles could again be sold to operators in municipal or private ownership.

By the mid-1970s Leyland owned all of Bristol and its product range had shrunk to the VRT

double deck bus chassis, LH / LHS

single deck small-bus chassis and RE

bus chassis (by 1976 built for export to Northern Ireland and New Zealand only).

The Bristol chassis factory closed in October 1983 when the final Bristol-built Olympian chassis was sent to ECW to receive its body. It became Devon General reg. A685 KDV. Olympian chassis production then moved to Leyland factories (in Lancashire).

So, bus and coach chassis were built in Bristol City over a 75 year period from 1908 to 1983.