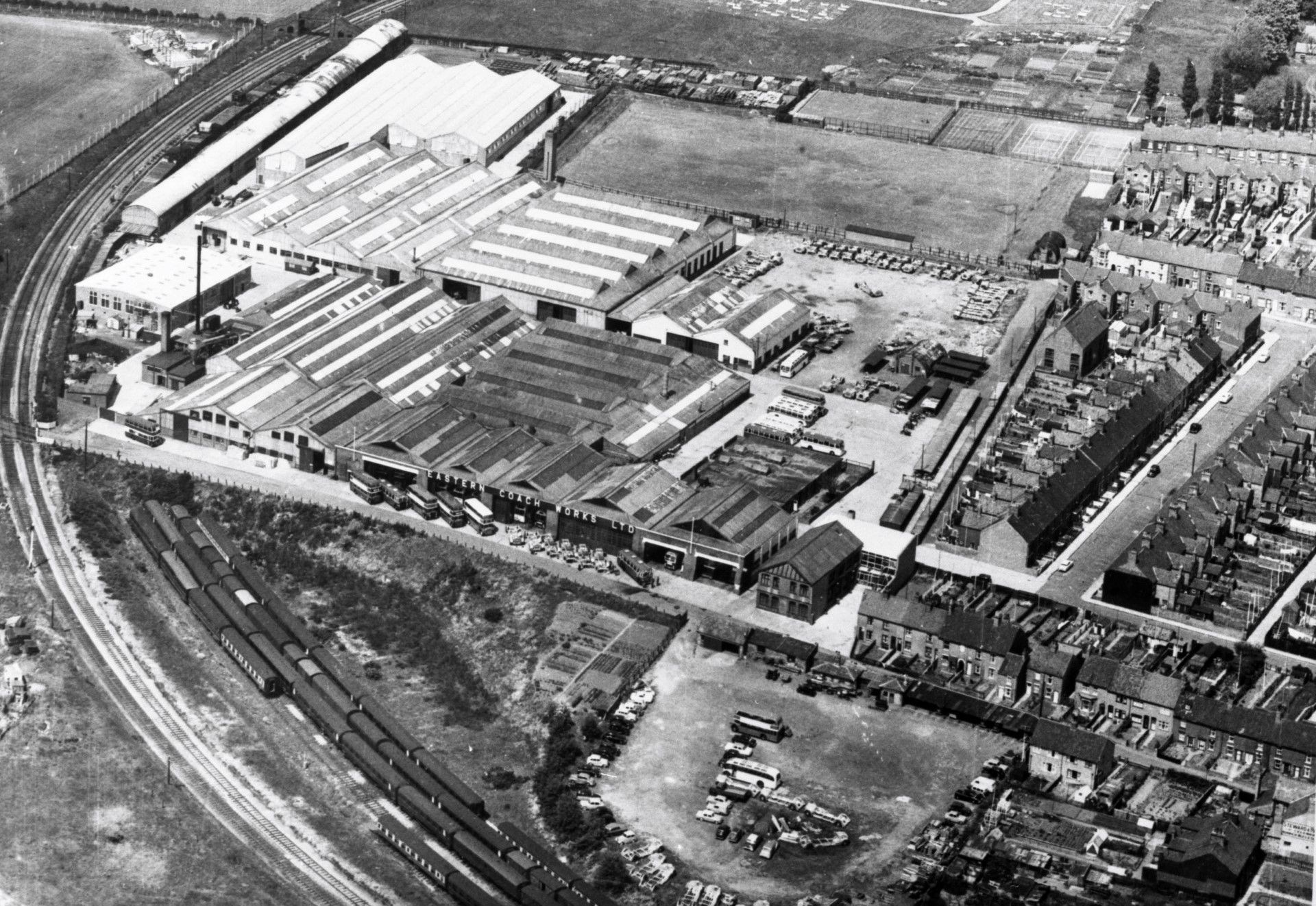

EASTERN COACH WORKS

-

Button

This logo was displayed inside at the front of all their coachwork.

-

OAX 8F

ButtonOfficial photograph taken at Eastern Coach Works factory on 23 January 1968 of OAX 8F, by Laurence Gall (Commercial photographer used by ECW).

-

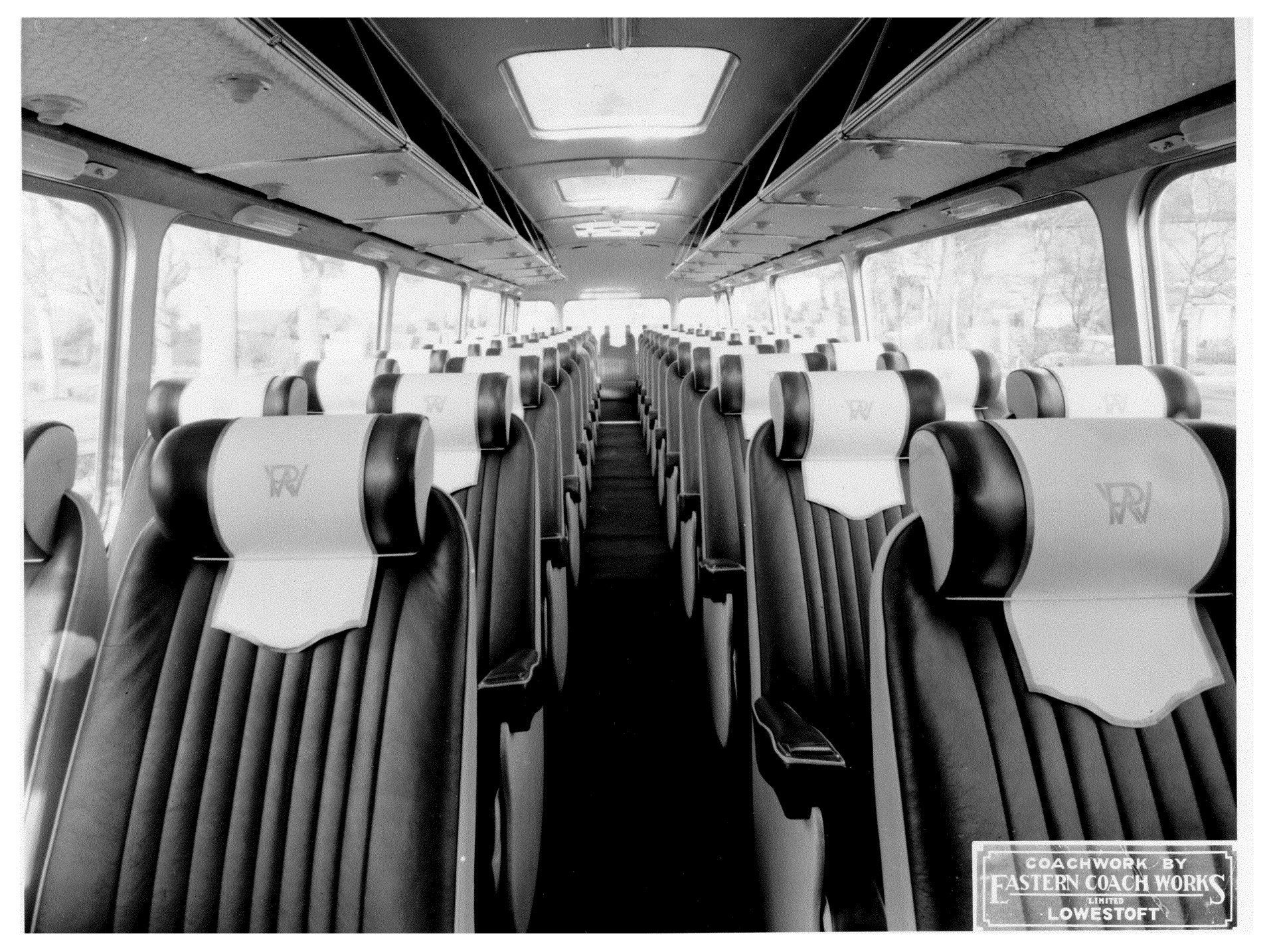

GWO 4D Interior

ButtonPhotograph taken on 4 January 1966 of GWO 4D at Lowestoft by Laurence Gall (the official ECW photographer).

-

GWO 4D interior

ButtonPhotograph taken on 4 January 1966 of GWO 4D at Lowestoft.

Images from the ECW Archive collection (courtesy of S Butler).

-

Original coachwork drawing - nearside.

Button -

Original coachwork drawing - offside.

Button -

Original coachwork drawing - interior seat layout.

Button -

Eastern Coach Works factory front doors.

Button -

Original coachwork drawing - front.

Button -

Original coachwork drawing - rear.

Button -

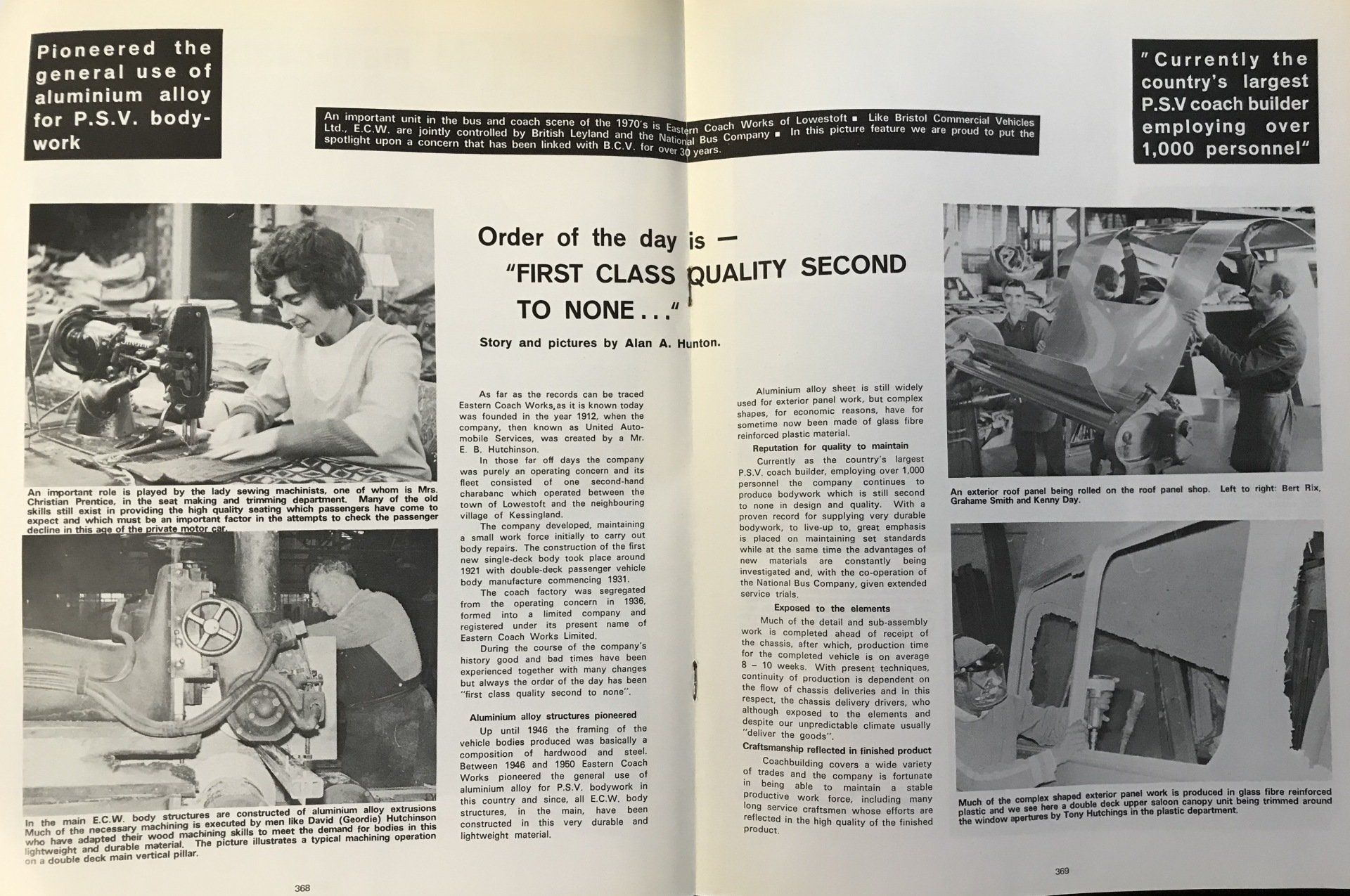

Article about ECW from 1971.

ButtonSection 1.

-

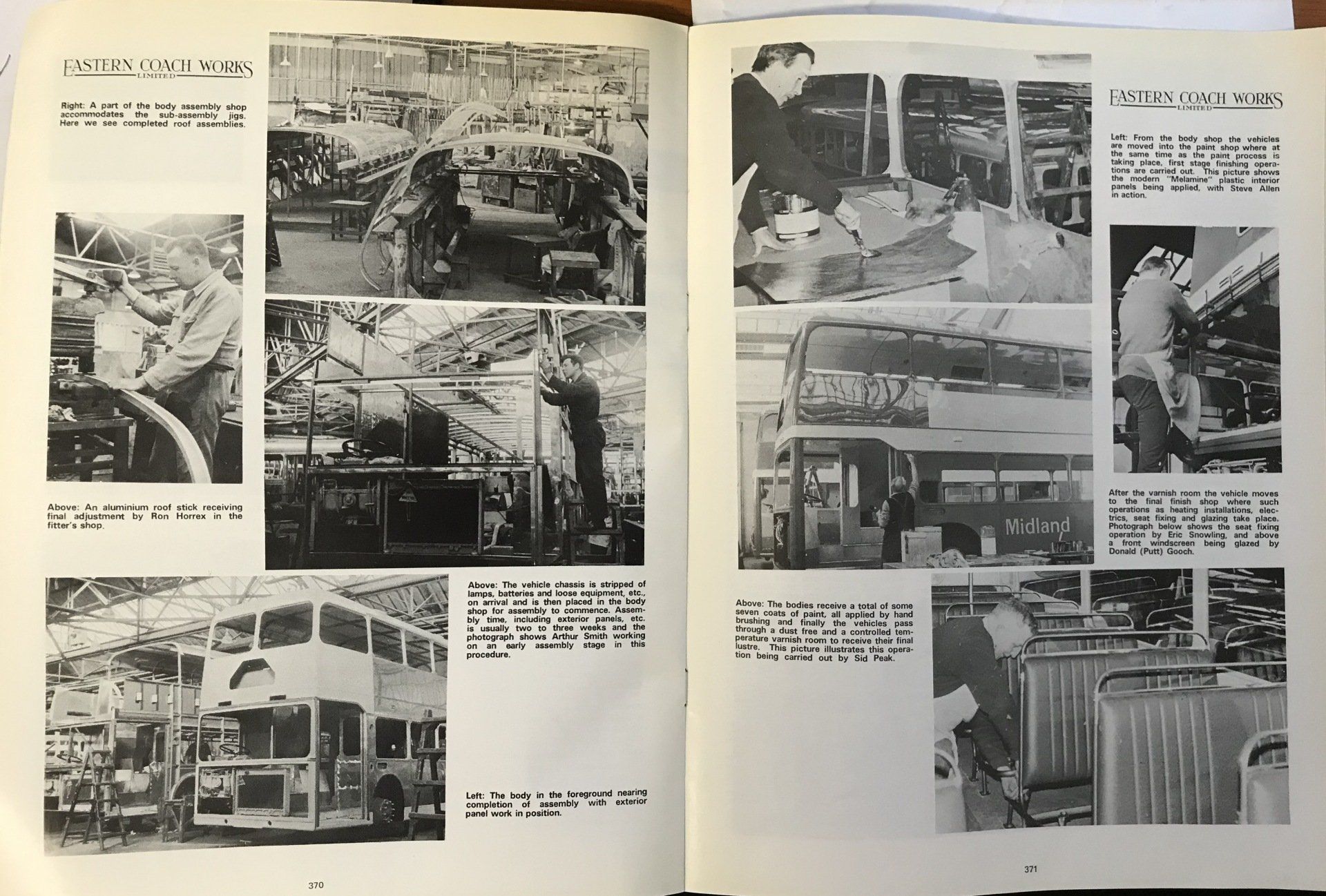

Article about ECW from 1971.

ButtonSection 2.

The skilled craftsmen at ECW manufactured most of the coachwork themselves by hand from raw materials - aluminium, steel, hardwood and fibreglass. However, they bought-in components from specialist manufacturers - here we list most of the suppliers ECW used to build our Ruby:

- Brifex - leather cloth material used on interior side walls; front & rear domes & underside of luggage racks.

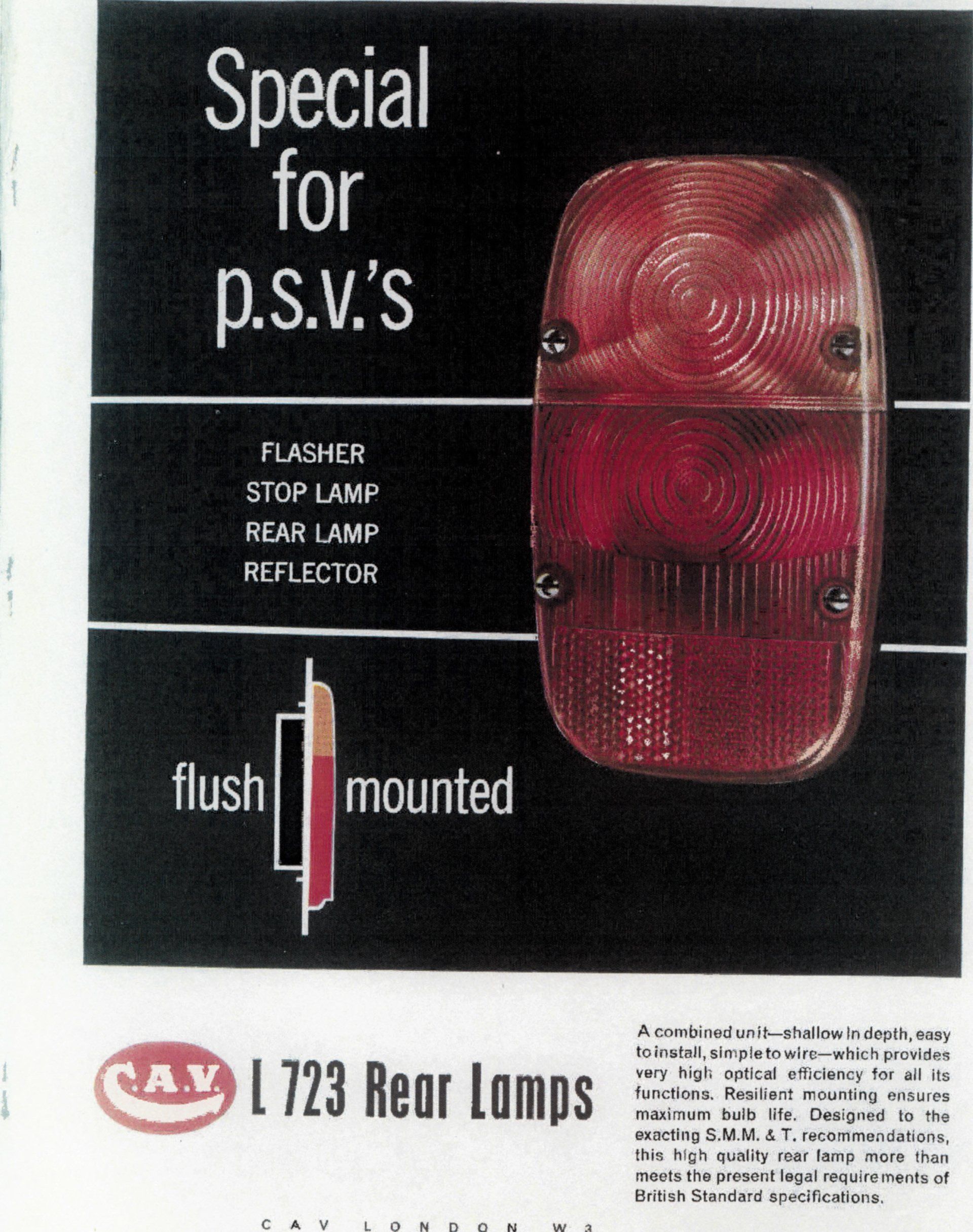

- CAV - electrical control panel, rear lights, fog light, door controls.

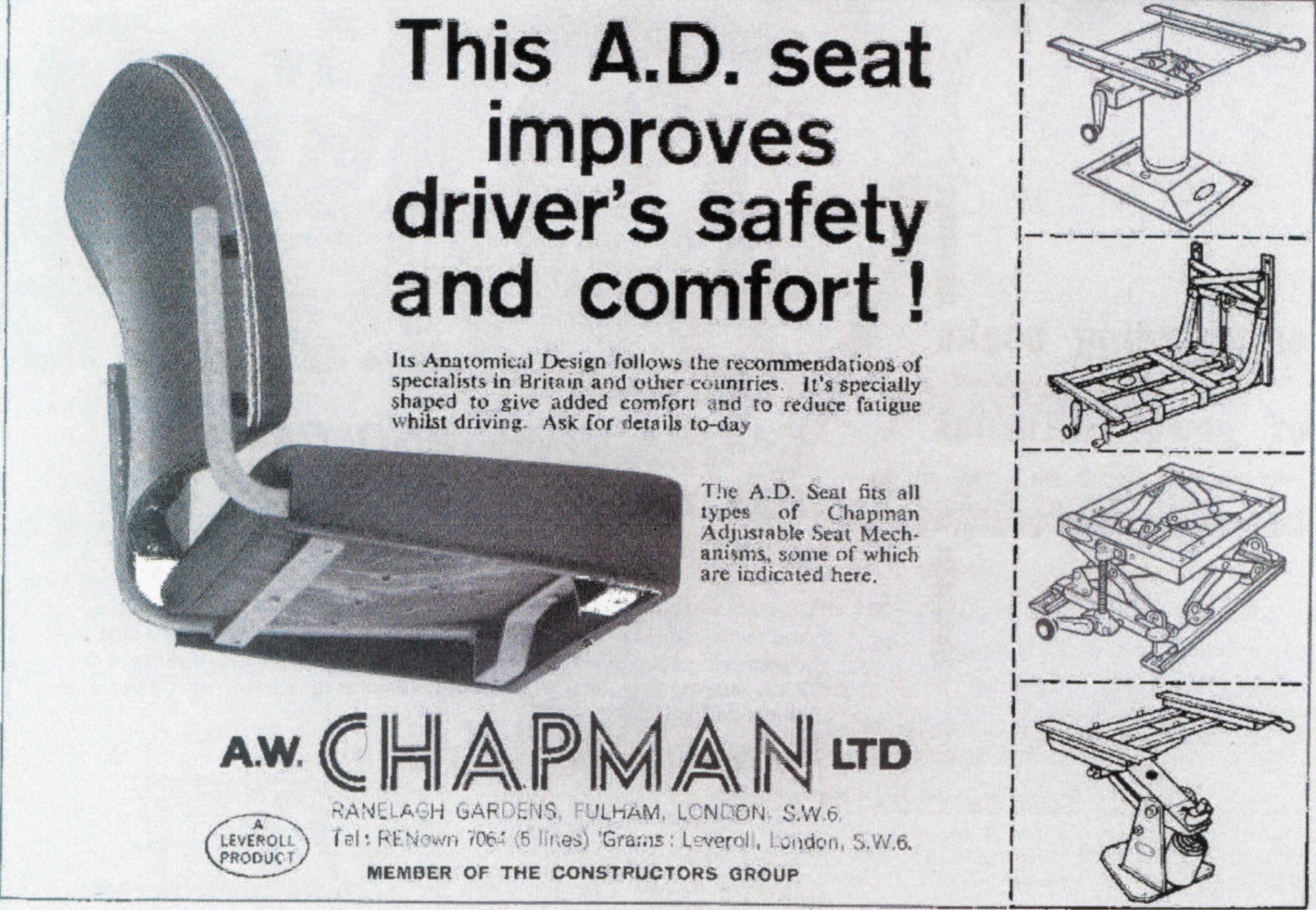

- Chapman - driver’s pedestal 'A.D type' seat.

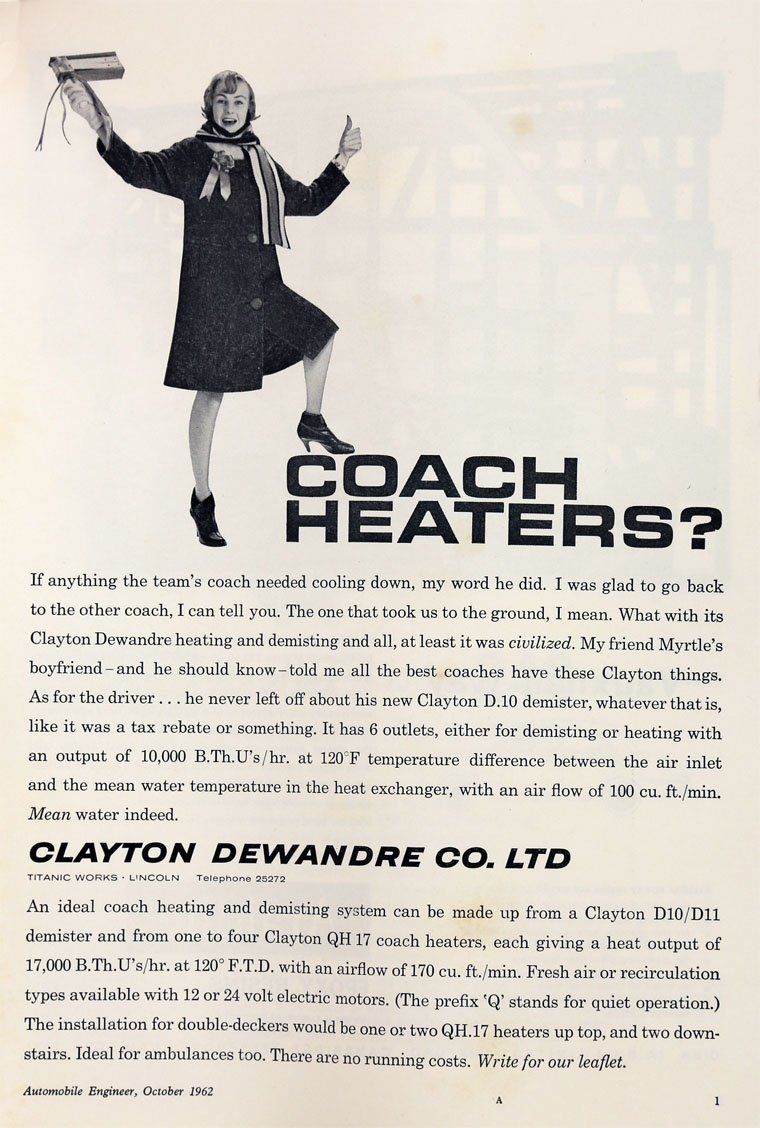

- Clayton Dewandre – floor-mounted saloon fan heaters.

- Frankmann - exterior front trafficator lights.

- Kelbus – destination blind winding equipment.

- Linoleum - flooring for luggage lockers & kick panels in saloon.

- Lucas - exterior headlight units.

- Nesthill - exterior rear view mirrors.

- Philips - interior fluorescent light tubes & ballast units.

- Rawlings - 'Vortex' roof-mounted ventilators.

- Simms - electrical control panels and switches.

- Smiths - electrical switch panel, trafficator switch, overhead air vents (under luggage racks).

- Treadmaster - cork vinyl flooring.

- Warerite - window panel laminated plastic inserts.

- Weathershields - opening sky-lights.

- Wilmot Breedon - chrome ash trays (installed in seat arm rests) and seat-back grab handles.

Pictured (below) are some original 1960's magazine adverts for some of the component suppliers listed.

-

CAV

ButtonSupplied traffic indicators.

-

CAV

ButtonAlso supplied rear light units.

-

Chapman

ButtonSupplied their AD drivers seat.

-

Clayton Dewandre

ButtonSupplied floor-mounted heater units.

-

Philips

ButtonSupplied their fluorescent interior lighting system.

-

Rawlings

ButtonSupplied their 'Vortex' roof ventilators.

-

SIMMS

ButtonSupplied their electrical control panel.

-

Warerite

ButtonSupplied laminate plastic sheeting for window surrounds.

www.redandwhitebus.com Website design & copyright: Radley Creative, Oxfordshire. 2024.